The pair coil problem

Louise Belfield investigates recent problems with pair coil that have caused frustration and financial losses for Australian fridgies.

Around 2020, fridgies across Australia began reporting unusual leaks in the pair coil within air conditioning systems they had installed. Fixing these problems has proven costly, but should the technicians be the ones to pay the piper?

The problem

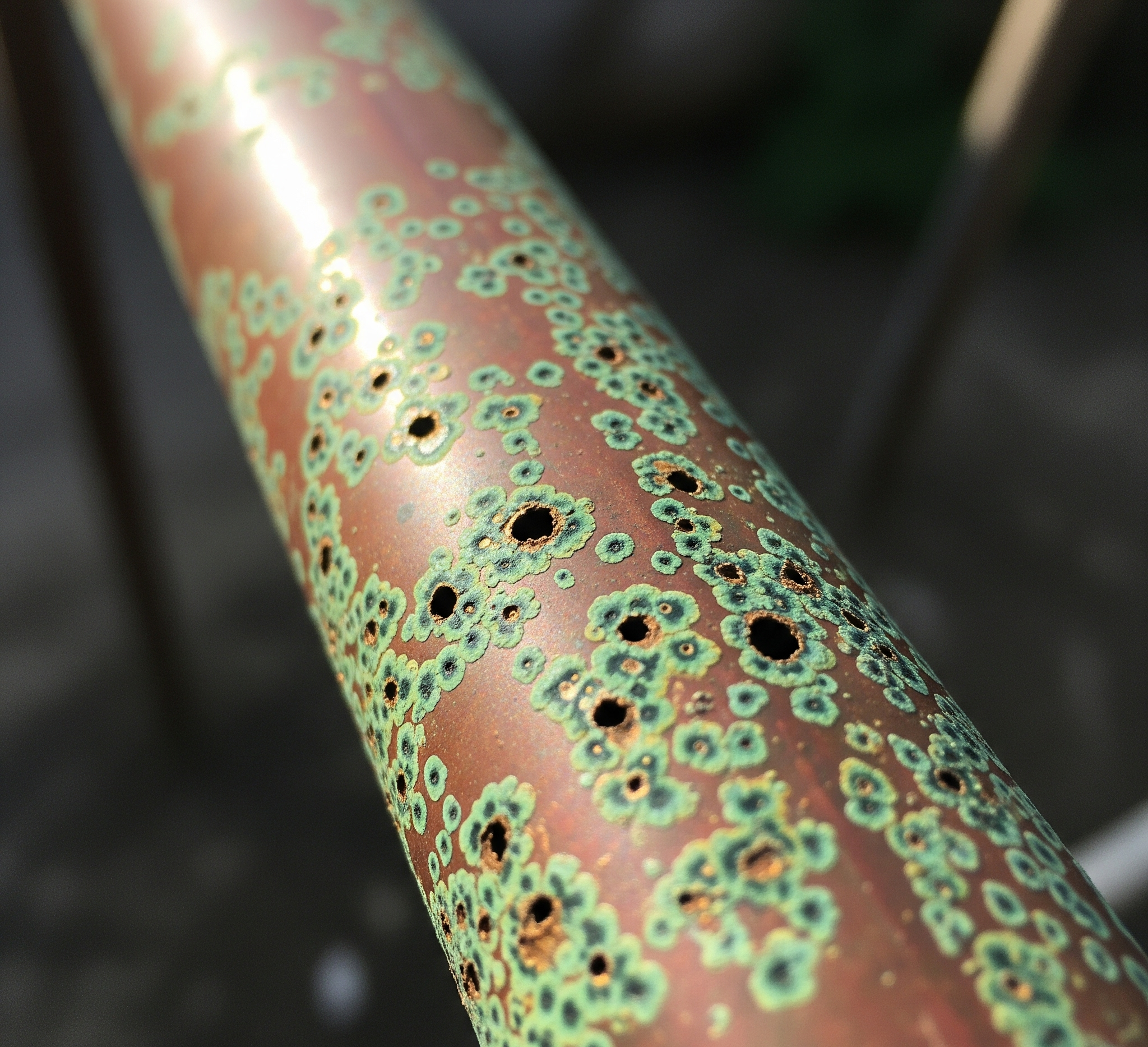

Pair coil is a type of copper piping with insulation on the outside that is commonly used in air conditioning. In recent years, installers of this type of piping have been called back to jobs by unhappy customers and finding small pinhole leaks in stretches of pipe where you wouldn’t normally expect them. Pipes have been corroding, systems have stopped working properly, and refrigerant has been exposed to the atmosphere in what appears to be classic cases of corrosion known as “ant nesting”.

Installers have been called out to make repairs and have literally had to pay the price. But opinion is divided as to where the blame lies.

Fridgies passed on their concerns to their suppliers, then the Australian Refrigeration Council (ARC). Ultimately, the Department of Climate Change, Energy, the Environment and Water (DCCEEW) investigated the complaints and determined through a steering committee that the fault lay in how the air conditioners had been installed.

According to the DCCEEW investigation, if the ends of the pair coil were not sealed properly and the bends were not done carefully, this could lead to moisture gathering between the insulation and the pipework, leading to corrosion.

Wholesalers claimed they had tested the pair coil and found that it was okay. Contractors did not all agree.

Leaking at the coal face

It’s all been a bit of a nightmare for Daniel Nigro, a fridgie of some 12 years and director of All Round Heating & Cooling in metropolitan Melbourne.

According to Nigro, the issue first raised its ugly head in 2022, with the ant nesting occurring between bends. Since then he’s had another 24 cases, but says they have been less frequent of late. Like many others in his field, he associates the problem with the COVID-19 pandemic.

“I have been working with pair coils from day one and never had any issues pre-COVID.”

Daniel Nigro

“Something changed around then,” Nigro says. “Pipes started corroding, with small pinholes that you can’t see, and this generally happens when moisture pools in low points or where there is a bend in the pipe.

“The pipe turns a green purple, generally within two years of the install date. I’ve had a job where it happened within three months.”

Nigro found using cable ties to seal ends has helped, but like other fridgies, the cost of rectifying the leaks has fallen to him.

“I’m bearing the cost labour wise, but luckily I have a branch manager who has been very supportive in helping me out where he can.”

In addition to cable-tying the ends of all installations, Nigro also siliconed the insulation on all ducted jobs where moisture can pool on the U-bend, and he hasn’t noticed any issue since.

“It’s been very time consuming,” he says. “There’s also a lot of paperwork to do to fix these issues. I write everything down just in case any class actions do occur. And it’s been very frustrating trying to explain this to customers.”

Common concerns

Many other installers echo Nigro’s comments, voicing their opinions loudly on the “Crappy Refrigeration” Facebook page.

One says he has also been dealing with the problem since 2020, having had to rectify “well over 50 cases now and still going”.

Another fridgie reported 16 cases over the past two years, generally about a year after installation. He no longer uses white insulated pair coil because of this. “It has cost thousands to rectify and no one has any answers or accepts liability for this,” he says.

In his opinion, it is the insulation that is causing the issue. Even after joining new pipe, “pinholes on the liquid line and green corrosion” occurred just 12 months later, with the insulation then resembling jelly, he says. “There was possibly something they couldn’t get through COVID so they substituted it with something else.”

Another installer observes: “It always [occurs] in the same spot [in a bend at rear of outdoor unit]. It’s a massive issue.”

“All leaks are on the liquid line and not related at all to poor installation practices. I suspect poor quality copper imported through COVID. [I am told] there are only a handful of cases throughout Australia, but my fear is that many companies are yet to find their failed copper runs.”

Another company reports having its first issue with this on an install done almost five years ago. “The copper split. A tech [from a major company] claims this is happening very frequently and says it’s not due to poor installation but the quality of pair coil.”

Causes of corrosion

Martin Lynch, Affil.AIRAH, is a former mining professional who has managed a renewable energy business for the past 15 years. He is currently undertaking a PhD at the University of Queensland focusing on substitutes for copper.

Lynch notes that pinpointing the chemical reactions behind the ant nesting issue is key to working out who or what is at fault.

“The first thing to do is determine what type of corrosion is happening.”

Martin Lynch, Affil.AIRAH

“There have been some suggestions that formicary corrosion is the problem,” Lynch says. “But this is a type of corrosion that occurs when a copper pipe is exposed to the air, and airborne chemicals – such as wood smoke or fumes from cleaning fluids – collect on the pipe surface. In the presence of water and oxygen these chemicals break down to formic or acetic acid, and they eat into the pipe. As these cases of corroded sections of pipe are not exposed to the air, it is very unlikely to be formicary corrosion.”

Lynch suggests that the problem is also probably not due to internal corrosion – which can be caused by refrigerant breaking down in the presence of moisture to form hydrofluoric acid – because the first-hand observations all say that the corrosion is forming on the outside of the pipe. This, then, suggests that it is general pitting.

“This (pitting) occurs when the surface of the metal comes into contact with a mixture of water and (most often) chlorine compounds,” Lynch says. “Together these can form hydrochloric acid, and that will eat through copper pipe. The speed at which this occurs varies with the concentration of the acid. It can sometimes occur in a matter of months.

“And since the cause of the corrosion seems not to be clearly established at the moment, one place to look is at the composition of the inner surface of the insulation,” Lynch says.

“The question then needs to be asked: has there been a change such that, in the presence of water, there are chlorine compounds, or other potentially corrosive chemicals being released from the insulation when that wasn’t the case before?

“In the meantime, preventing any water ingress between the pipe and the insulation seems like a good preventive measure.”

Costly corrosion

Corrosion is a leading cause of refrigerant leaks, leading to costly call-backs and threatening the environment as refrigerant is exposed to the atmosphere.

The two most common forms of external corrosion in the HVAC&R industry are pitting and formicary corrosion. These can occur anytime from a few weeks to one to four years after installation. Identifying the type of corrosion is the first step to determining the cause of a problem such as the one reported in pair coil.

General pitting

General pitting is caused by aggressive anion (negative ion) attack on copper tube, which is an abundant source of cations (positive ions).

Large pits resembling bite marks characterise general pitting. These will eventually break through to the inside of the tubing and create leaks. Chlorides are the most common cause.

Formicary corrosion (“ant nesting”)

The word “formicary” stems from the French word for ants, which would build nests on warm copper pipes that were out in the open and exposed to rain.

Martin Lynch, Affil.AIRAH, says ants produce formic acid, which, when it comes into contact with copper, can eat into the pipe if it’s in the presence of water and oxygen.

Formicary corrosion occurs on the outside surface of copper pipes, not on the inside. These days, it is more likely to be caused by man-made chemicals rather than ants. Fumes from cleaning agents or cosmetics – as well as smoke-borne chemicals – can generate formic acid when they come into contact with copper pipe.

“These chemicals can degrade and form acids. If they form formic acid or acetic acid, then there could be a problem,” Lynch says.

“If the pipe is dry, nothing will happen. But if its wet – such as when airborne moisture condenses on the copper pipes of an air conditioner – then the ground is laid for formicary corrosion.

“So, the essential ingredients for formicary corrosion are chemicals floating around in the air, copper pipe exposed to that air, and moisture condensing on the pipes.”

DCCEEW findings

In 2023, the DCCEEW convened two advisory group workshops with industry peak bodies including suppliers, installers, and other experts on the concerns of leaking pair coil. The ACCC attended the advisory group to highlight the rights of technicians as consumers.

The DCCEEW also conducted an industry survey on pair coil issues, including questions on pair coil brand and specific issues observed. The survey results showed technicians had concerns with a range of different types of pair coil on the market, with no one brand or style of pair coil identified as more at fault.

Following the workshops, the advisory group recommended that pair coil issues were deemed to be a contractual issue best raised with the manufacturer of the pair coil.

In 2024–25, the DCCEEW worked with AIRAH to review, update and publish parts 1 and 2 of the Australia and New Zealand Refrigerant Handling Codes of Practice. This included providing more detail on best practice for pipework installation and maintenance.

Ongoing frustration

While the issue continues to cause problem, no action has been taken to independently test products or recall them if they were found to be faulty. Many HVAC&R contractors are still encountering problems – and bearing the financial burden of the issue.

Lynch says he would be cautious about laying the blame for ant nesting on poor installation practices given how many experienced installers have reported that they had not seen this type of corrosion prior to 2020. The fact that these issues have emerged post-2020 suggests that something else may have changed, he says.

Nigro disagrees strongly with the findings of the DCCEEW.

“Pair coil has been around for a very long time with no issues ever occurring,” he says.

“It’s the quality of the product that is the weak link here. The copper deteriorates and this should not happen. There were never any issues pre-COVID.”

Daniel Nigro

“I’m not sure whether it’s the copper itself or the insulation causing it, but it’s not an installation fault.”

Read all about it

The skills workshop from issue 97 of HVAC&R News covers the basic types of corrosion in copper piping. You can access this three-page document via the AIRAH website.

PREV

NEXT

Comments

-

Years ago I became aware of a phenomenon called Microbiologically Induced Corrosion (MIC). MIC can affect a wide range of metals including steel, aluminum, and copper, and can appear as pitting corrosion as shown in the article photo. The rate and severity of MIC are influenced by environmental conditions like temperature, pH, salinity, and nutrient availability (i.e. food source). I witnessed MIC appearing as severe pitting corrosion on the surface of aluminum piping when covered by closed-cell rubber insulation (“Rubatex” or “Armaflex”). Our conclusion was that particular type of insulation was providing a food source that the microbes really found tasty, creating a bio-cell with the attendant local low pH byproducts which then initiated the pitting. I highly recommend a close look at the corrosion products on the copper pipe by a competent forensic metallurgical lab with an eye to MIC fed by the insulation material. Bruce I. Nelson, P.E., MAIRAH (www.bvngineering.com)

-

So another investigation and talk fest, with no action or outcome.

No responsability or accountability from suppliers.

Small business has to cop the expense.

ARC cant do anything.

Why am I not supprised. -

It’s great that AIRAH is covering issues that are seen by the trade and to read about what could be causing the corrosion. Well done to all involved in the article.

-

stop using cheap poor quality pair coil and take responsibility as a qualified tradesperson with an Arctick RHA/RTA License to manage refrigerant loss and product life cycle and use quality products in the 1st instance , and also ensure your pipe/insulation installation is vapor sealed with no air gaps between the pipe and insulation and doing the right thing for the environment, end user and our trade

-

Where are any independent lab tests on the purity of the copper imports versus some older samples? There has to be a purity change from the 80’s-00’s(maybe 10’s) to todays almost entirely imported material surely? Are we trying to say that everyone properly vapour sealed insulation back then and chlorines didn’t exist in the air or in insulation blowing agents? Copper use to handle most industrial or otherwise environments, rough insulation practices where almost as normal as todays, or polystyrene and/or moderate chemical exposure without any dramas for decades. Now they (suppliers/importers) say simply using a bubble up leak detector product that has also been around for years can be blamed for a 2 year failure and reject liability… Come on now, we all know how quality works within the imports game we are now stuck with… Why not mandate a local lab sample test on each import batch, otherwise smelt it here with batch certificates. Costly, but protective of various industry, trades and the good old quality expectation within our Australian Standards (cough) of 99.9% copper content.

-

What about electrolytic effect, I have found liquid lines having the problem and not more than 50mm parrallel the suction line has no discolouration, both under went the same conditions in installation.

The stray currents from electrolytic effect causing static charge became the focus as the only differing characteristic was the pipes contents, pressure and state of refrigerant.

It’s a joke that this isn’t being taken seriously and a full movement to ensure the copper pipe work we are getting is not having greed drive percentages of iron ore and other materials.

-

As a material and corrosion Engineer, I agree the first step is to determine the corrosion type; chemical study, SEM and spectral analysis will be helpful in this research. Then we can find the root causes and potential solution. As these is a new emerging problem, material may be a problem.

-

What a load of rubbish, people paid to cover other people because there manufacturers won’t care and the amount of money they would have to pay out would hurt (probably not). Oh well, we will just leave it to the integrity of business owners to look after there customers.

No problems before 2020

No problems now, seem like it’s magically solved

Advertisements

Recent news

- Additional keynote announced for HVAC26

- Dog days: how our best friends affect IAQ

- Cert II training and impact – have your say

Latest events

- Additional keynote announced for HVAC26

- PSO to host focus groups at AIRAH Hobart Industry Night

- Huge attendance for 2026 ASHRAE Winter Conference

Louise Belfield

Louise Belfield

Leave a Reply