Researchers develop new cooling fabric for clothing

A new textile innovation co-developed by University of South Australia (UniSA) scientists could keep wearers cooler and drier in extreme heat.

Partnering with researchers from Zhengzhou University in China, UniSA materials scientist Professor Jun Ma from the Future Industries Institute has helped to create a lightweight, breathable and biodegradable fabric that reflects 96% of the sun’s rays in outdoor conditions.

The moisture-wicking composite fabric is described in the journal Nano Research. In outdoor field tests, it lowered skin temperature by 2°C under direct sunlight and by 3.8°C at night compared with bare skin.

How it works

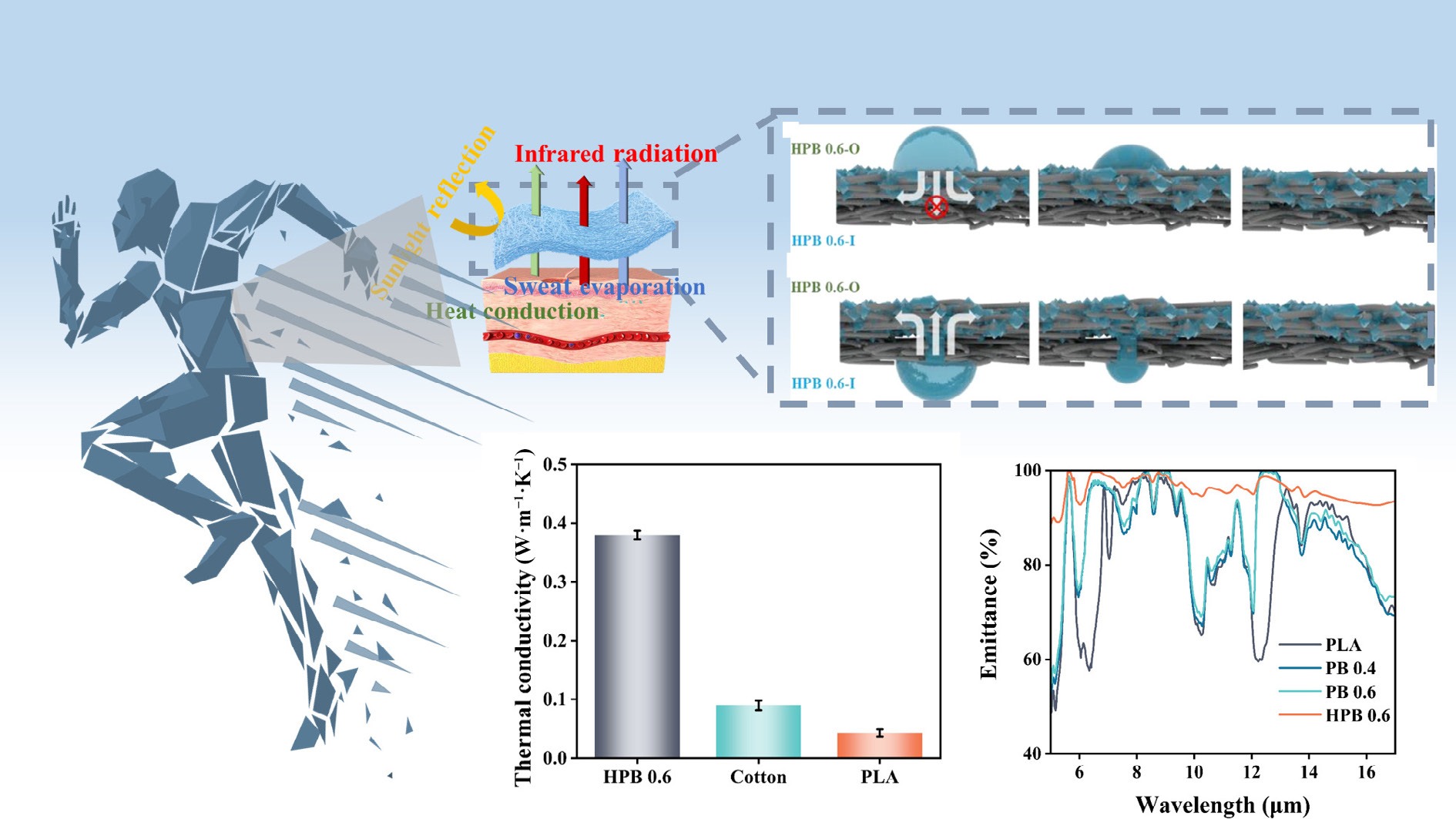

While cotton-based fabrics trap heat and sweat, the newly developed polylactic acid/boron nitride nanosheet material actively releases warmth while keeping the skin dry.

“We’re seeing more frequent and intense heatwaves globally, and that has serious implications for outdoor workers, athletes and people living without access to air conditioning,” Ma says.

“Our goal was to design a smart, sustainable fabric that passively regulates body temperature – not by using energy, but by harnessing natural physical processes.”

Using a scalable electrospinning technique, the researchers embedded boron nitride nanosheets – highly thermally conductive, lightweight particles – within a biodegradable polylactic acid fibre matrix. The result is a white, nanostructured fabric with high solar reflectance and five times more breathability than cotton.

“The combination of high solar reflectance, heat radiation and moisture control means that the wearer feels noticeably cooler and drier,” Prof Ma says.

“It’s particularly beneficial for people who work outdoors in construction, mining, agriculture or emergency services, where heat exposure is both a comfort and safety issue.”

Future use

The study’s lead author, Associate Professor Yamin Pan from Zhengzhou University, says the collaboration with UniSA was instrumental in testing and refining the material’s thermal performance.

“UniSA’s advanced materials expertise helped us evaluate the heat transfer and radiative cooling properties of the fabric,” says Pan. “The partnership shows how international collaboration can accelerate the development of smart, sustainable materials.”

The researchers believe the technology could be easily adapted for sportswear, uniforms, outdoor workers, and even military and emergency clothing designed for extreme heat.

Ma says the team is now exploring potential commercial applications and large-scale manufacturing opportunities.

“The electrospinning process is straightforward and cost effective, which means the fabric could be produced at industrial scale,” he says. “With further development, it has the potential to transform the next generation of cooling clothing.”

Read the full paper

The full research paper is available for free in Nano Research.

Image courtesy of the University of South Australia (UniSA)

PREV

NEXT

Comments

Advertisements

Recent news

- February–March issue of HVAC&R News out now

- Reliable Controls marks 40-year milestone

- Conex Banninger and Reese launch enhanced fitting range

Latest events

- The path ahead for the VEU – industry webinars

- Additional keynote announced for HVAC26

- PSO to host focus groups at AIRAH Hobart Industry Night

Nick Johns-Wickberg

Nick Johns-Wickberg

Leave a Reply