Striking a balance: clean air and sustainability

The sponsored post by Camfil examines how good indoor air quality (IAQ) and improved energy efficiency can go hand-in-hand.

Introduction

Clean air is essential for every facility, helping protect people, productions and processes from airborne contaminants. In the wake of the COVID-19 pandemic, the importance of maintaining indoor air quality has become more evident than ever before.

The need for superior air quality in healthcare facilities is readily apparent, as it reduces the risk of airborne transmission of diseases among patients who are often more susceptible to infections and respiratory issues. This helps protect people’s lives and creates a conducive environment for healing and recovery.

However, clean air is not just an imperative for those who are ill or vulnerable to illness. It is a critical factor for ensuring the safety and wellbeing of people in every setting. For instance, industrial facilities reap substantial rewards from enhanced air quality. By minimising airborne contaminants, these environments become safer for workers, leading to a decrease in occupational health issues and increased overall efficiency.

In commercial offices, poor air quality has been linked to lower productivity. A 2004 study of office workers in a Denmark call centre concluded that poor air quality could reduce the performance of office workers by 6–10%. Poor air quality is also associated with higher absenteeism, as occupants experience a greater risk of health- related disruptions.

In educational institutions, clean air has been found to enhance concentration and cognitive function among students, positively influencing their learning experience and academic performance.

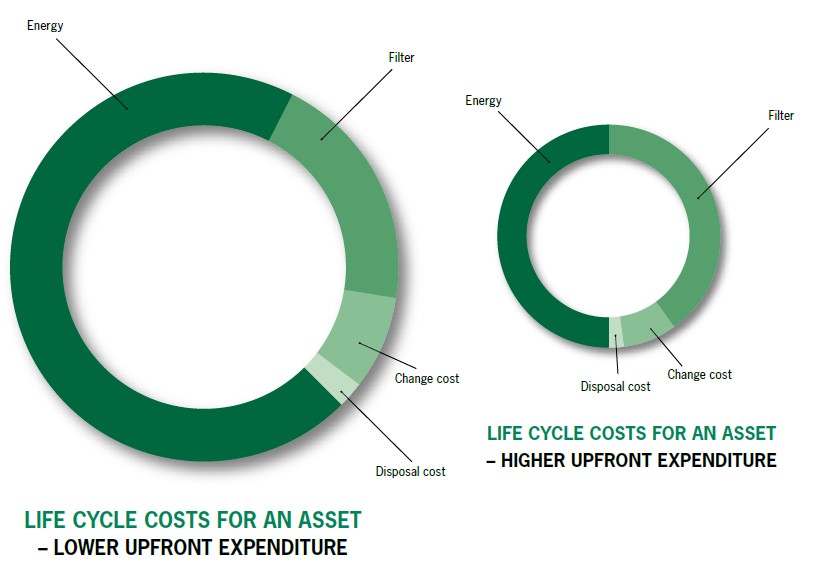

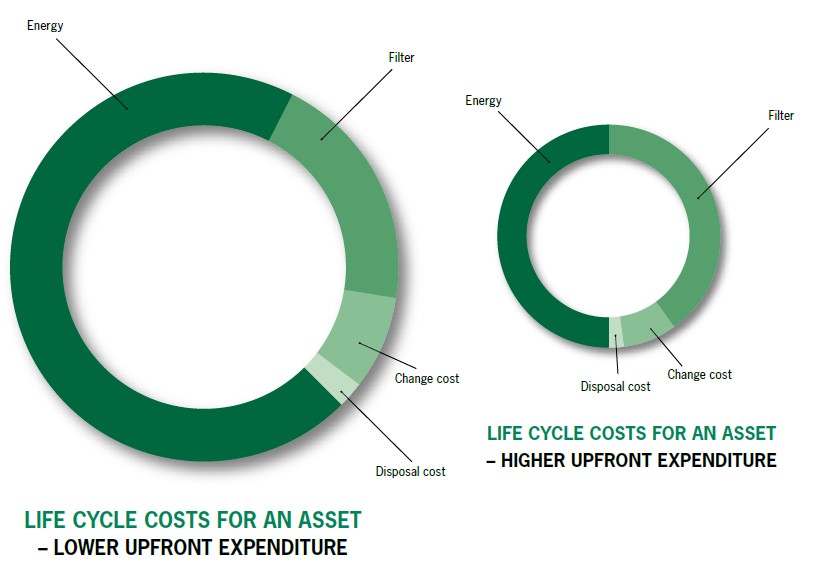

A growing recognition of the importance of clean air, coupled with escalating concerns around the environment and sustainability, is reshaping the way societies approach air quality. While improving air quality in a facility has often been associated with an increase in energy and operation costs, this doesn’t have to be the case. Investing in filtration technologies can improve air quality and achieve a reduction in energy costs at the same time. This is where life cycle cost (LCC) analysis serves as a critical tool for guiding decision-making, helping assess factors beyond the initial cost.

LCC is a method used to evaluate the total cost of owning and operating a system over its entire life cycle. Life cycle costs take into account all the costs associated with an asset or system over its entire life span, including initial purchase, installation, maintenance and replacement costs.

When selecting filtration systems, LCC should also take into account the costs of downtime, energy consumption and environmental impact. Through this holistic approach, facilities can guarantee the continuous supply of clean air, ensuring the wellbeing of occupants, enhancing productivity and contributing to a greener, more environmentally conscious future.

What is LCC?

Life cycle cost analysis involves evaluating the total cost of owning and operating an asset, which includes not only the initial investment (capex) but also ongoing operating costs (opex) such as maintenance, energy consumption and replacement expenses.

Increased upfront expenditure in the form of capex investments can significantly reduce opex in the long run. By investing in high-quality assets initially, owners can enjoy benefits such as reduced maintenance requirements, lower energy consumption and longer lifespan of the equipment. These factors contribute to substantial cost savings over the asset’s life cycle.

Why upfront investments lead to long-term gain

Assessing the life cycle costs of filters is a strategic approach that fits into the broader framework of responsible and sustainable business practices promoted by environmental, social, and governance (ESG) considerations, and this can have significant tax benefits. ESG considerations have expanded, encompassing tax governance, transparency, transfer pricing, decarbonisation and environmental taxes.

The intersection of ESG and taxes introduces several complexities and requires businesses to stay updated on global environmental tax developments and assess their impact on operations. For instance, the reformed Australian Safeguard Mechanism may require businesses to incur compliance costs associated with emission reduction measures. However, applying LCC can support businesses to invest in cleaner technologies that improve efficiency and result in long-term cost savings.

The evolving environmental tax landscape poses challenges and opportunities, with potential tax incentives for businesses that invest in green equipment or initiatives. For example, on April 30, 2023, the federal government announced it would provide businesses with annual turnover of less than $50 million with an additional 20% deduction on spending that supports electrification and more efficient use of energy.

As tax becomes a key driver of business change and governments use it to incentivise environmentally responsible behaviour, businesses must align tax policies with ESG commitments. Investors and stakeholders increasingly scrutinise companies for ESG and tax transparency, making a transparent tax policy a powerful tool to build trust.

Optimising filter systems

Applying LCC to filter systems also provides valuable insights that can be used to improve their design and operation. By analysing the costs associated with different filter types, buyers can identify areas where cost savings can be achieved, such as selecting more efficient filters or optimising maintenance schedules.

Evaluating the performance of different filters and their impact on system efficiency also enables buyers to make informed decisions about which filters to use and how to optimise ventilation system operation to achieve better performance.

LCC also helps understand maintenance requirements, and this information can then be used to develop effective maintenance plans that minimise downtime and maximise system performance. Through insights into the expected lifespan of filters and other components, conducting LCC helps make informed decisions about when to replace filters to avoid unexpected failures or excessive maintenance costs.

By considering factors such as energy consumption, waste generation and disposal costs, the environmental impact evaluation of filters during LCC can help identify opportunities to reduce the environmental footprint of the filter system.

The benefits of enhanced indoor air quality

Enhanced indoor air quality offers a myriad of benefits, significantly impacting both the wellbeing of individuals and the overall productivity of businesses.

Understanding these advantages is crucial for creating healthier and more efficient indoor environments.

Here are the key benefits of enhanced indoor air quality:

- Reducing the risk of airborne virus transmission

As the COVID-19 pandemic has demonstrated, enhanced indoor air quality plays a vital role in reducing the risk of airborne virus transmission. Proper ventilation, air filtration and purification systems help minimise the concentration of airborne pathogens, including viruses.

The release of new guidelines by ASHRAE (the American Society of Heating, Refrigerating and Air-Conditioning Engineers) underscores the need for Australia to further reduce the risk of COVID-19, influenza and other airborne virus transmission in homes, offices, schools and hospitals during periods of high risk.

Following the pandemic, the US government commissioned ASHRAE Standard 241, which establishes greater thresholds for outdoor air exchange rates, with certain settings requiring doubling the current outdoor air supply to achieve pathogen-free air rates. It also provides a framework for facilities managers, building engineers and tenants to design for safe air, considering a combination of outdoor air and fresh air with the use of HEPA filters.

- Reducing the health impacts of particulate matter

According to the World Health Organization (WHO), indoor air pollution leads to a number of non-communicable diseases such as lung cancer, stroke, ischaemic heart disease and chronic obstructive pulmonary disease (COPD).

Exposure to PM1 – particulate matter with a diameter of one micron or less – is linked to higher incidence or severity of various diseases, consequently reducing the overall quality and length of life for individuals affected.

Many studies have shown that PM1 contributes to greater respiratory disease, especially compared with other particulate matters. Exposure to PM1 has also been found to increase the odds of cause-specific cardiovascular disease mortality.

Moreover, there is also evidence that PM1 has an impact on the gut microbiota of mothers and newborns. Additionally, a study of school-age children and adolescents in China found that exposure to particles and nitrogen dioxide was associated with a higher prevalence of childhood obesity.

Enhanced indoor air quality systems, equipped with effective filters, can capture and remove these harmful particles, improving the overall quality and length of life of occupants.

- Reducing the health impacts of VOCs and molecular contamination

Maintaining a healthy and clean indoor environment is vital for ensuring individuals, employees and students are performing at their best. For example, a recent study conducted by researchers from the Netherlands and the US found that competitive chess players perform worse when there is more particulate matter (PM2.5) in the air.

Lower indoor air quality is also associated with building-related symptoms such as tiredness, headaches, dry eyes and stuffy or runny nose and sneezing. These symptoms are estimated to be responsible for a 2% reduction in productivity in office environments.

Conversely, when people are healthy, they are more likely to have higher levels of energy and focus, leading to increased productivity. Additionally, a comfortable and healthy indoor environment increases employee morale, creating an atmosphere that is more conducive to collaboration and innovation.

Maximising productivity

Well-ventilated and clean indoor spaces have been shown to enhance cognitive function, concentration and overall work performance. Several studies and research findings have demonstrated the impact of indoor air quality on the productivity of individuals in various settings, including schools and workplaces.

A study of two call centres in Shanghai and Nantong, belonging to China’s largest travel agency, showed a direct link between the level of the Chinese Air Quality Index (AQI) and worker productivity.

The call centres were deliberately chosen since they routinely monitored their output. It meant that the researchers had access to exact measures of each worker’s daily productivity. By linking each worker’s output to the daily measures of the outdoor air quality and the weather, they found that higher levels of air pollution resulted in fewer calls completed each day.

If the Air Quality Index was up by 10 units, the number of daily calls handled by each worker would decrease by an average of 0.35%.

The researchers estimated that even a modest drop in air pollution could potentially increase productivity in the Chinese service sector by billions of dollars per year. They also concluded that the effects of air pollution likely affect major metropolitan areas all over the world in similar ways.

Another recent study by the Harvard TH Chan School of Public Health measured the impact of air quality on employees’ cognitive function, including response times and ability to focus, over a one-year period. Participants were studied in offices across six countries working in a variety of fields, including engineering, real estate investment, architecture and technology.

The study found that increased concentrations of PM2.5 and lower ventilation rates – measured using CO2 levels as a proxy – were associated with slower response times and reduced accuracy on a series of cognitive tests. Researchers also noted observations of impaired cognitive function at concentrations of PM2.5 and CO2 that are commonly recorded within indoor environments.

Incorporating these findings, businesses can proactively invest in enhancing indoor air quality, creating healthier and more productive environments for everyone. By prioritising clean indoor air, businesses not only safeguard the health of their employees and customers, but also pave the way for a more efficient and thriving workplace.

Balancing clean air and energy efficiency

While effective supply air filters require a significant amount of energy to operate, the health benefits they offer often outweigh the environmental costs. It’s also essential to recognise that efficient air filters not only contribute to cleaner indoor air quality but also have a direct impact on energy consumption.

When selecting air filtration systems, the priority is to reduce particles and pollutants indoors. However, there are certain factors to consider that impact energy consumption. Once the requirements for the degree of purification have been determined, the right filter can be selected.

In environments requiring the highest level of air purity, such as cleanrooms, hospitals and laboratories, HEPA filters, which are capable of efficiently capturing smaller particles, are essential. ULPA filters are often used in environments like semiconductor manufacturing and pharmaceutical production, where exceptionally clean air quality is imperative.

In environments where capturing larger particles is sufficient, bag filters are often used in conjunction with HVAC systems. An effective solution for removing dust, debris and contaminants from the air, bag filters are commonly employed in manufacturing facilities, commercial buildings and schools and universities.

Minimising energy consumption through filter design

Filters with a high pressure drop consume more energy, as they are more restrictive to airflow, leading to increased energy costs. Energy-efficient filters are designed to have a low initial pressure drop, allowing air to pass through with minimal resistance, therefore reducing the workload on the ventilation system.

Many people assume that filter efficiency is the largest contributor to initial pressure drop. However, it is the actual design of the filter that has the most impact. Increasing the amount of filter media, choosing the right media and optimising the shape of the bags results in lower pressure drop. Through a conical seam inside the bags that prevents them from blowing together (blocking the filter surface), airflow is further promoted, which also reduces energy consumption. This is done without compromising the efficiency of the filter (degree of separation).

Filters with lower initial pressure drop also capture particles efficiently without getting clogged too quickly, leading to less wear and tear. As a result, the need for frequent repairs and replacements diminishes, extending the lifespan of the equipment. Prolonging the life of filter systems reduces the need for manufacturing new units, thereby conserving resources and promoting sustainability.

Energy savings and new opportunities

Air filtration is a large component of energy cost because filters, by nature, create resistance to airflow. This forces the air distribution fans to work harder and use more energy. So, the question becomes: “Is it possible to achieve optimum filtration in each area of the facility, maintain rated efficiency through the life of each filter, and reduce energy costs?”

In fact, it’s possible to accomplish this, and much more. Energy efficient filters are engineered to significantly and immediately reduce HVAC energy expenditures while maintaining high contaminant removal performance and requiring less frequent change-outs.

Selecting the proper filter based on average lifetime resistance to airflow and the filter’s ability to maintain rated efficiency can save a facility 50% of its HVAC fan energy costs.

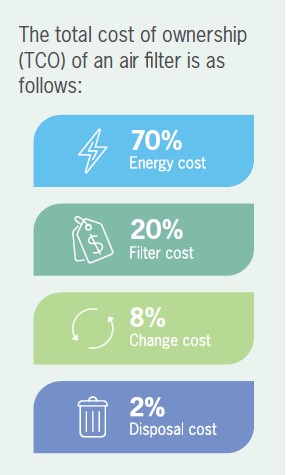

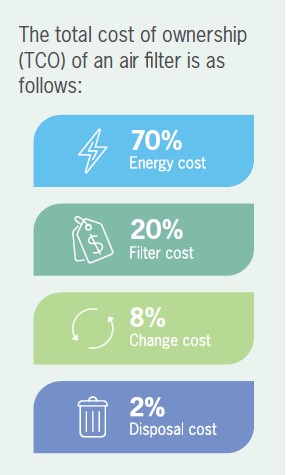

LCC software allows filter selections and change-out points to be optimised. LCC calculates the total cost of ownership (TCO), which includes all of the expenses associated with air filtration – the cost of the filters, the labour to install and remove them, filter disposal costs, and of course, the energy used to move air through the filters.

TCO is based on real-life performance, rather than simplistic mathematical charting. This powerful modelling software factors in multiple conditions specific to each installation, including hours of operation, utility rates, air contaminants, fan efficiency, labour and more. Most importantly, it allows discussions of filter alternatives to be based on science, rather than guesswork.

Energy consumption factors

A ventilation system with two filtration stages, that is a prefilter together with a fine filter, in general requires more energy than an identical system with only one stage – fine filter.

The energy consumption of a filter is a result of three factors: pressure drop, airflow, and particles concentration in the air before the filter. This means that for systems with prefiltration, the energy consumption of the fine filter will be lower than for the same filter without air pretreatment. This is because the air before the fine filter will have lower concentration of particles when the prefilter is present. However, even if the prefilter will reduce the energy consumption of the fine filter, it also requires a dose of energy for itself. This is why the total energy consumption of such a two-step system is usually higher than a system with only one filtration stage.

Conclusion

Clean air plays a critical role in ensuring the safety and wellbeing of people in every setting. With an understanding of the interplay between air quality, energy consumption and environmental impact, Camfil supports customers to make informed decisions when it comes to clean air solutions and the filters that can lead to vastly improved outcomes.

In addition to a reduction in energy use, a longer-lasting air filter has a significant impact on the environment, affecting various aspects of its life cycle:

- Reduced material usage – Fewer replacements reduce overall material consumption

- Lower GHG emissions – Extending the filter’s lifespan minimises emissions from material sourcing

- Decreased transportation – Fewer replacements result in reduced transportation emissions

- Decreased maintenance and labour – Longer-lasting filters require less frequent maintenance and replacement, reducing associated emissions

- Minimised waste and landfill emissions – Longer-lasting filters generate less waste and emit fewer pollutants in landfills, including fewer gases from transport to landfill

- Mitigated harmful gas emissions – Proper filter disposal minimises the release of possible harmful gases. In addition, using fewer filters ultimately reduces ESG Scope 3 emissions.

About Camfil

For over 60 years, Camfil has been a leading manufacturer of premium clean air solutions, and designs low average pressure drop air filters in all filter classes. Founded in Sweden in 1963, Camfil now provides commercial and industrial systems for air filtration and air pollution control across the globe. Its solutions are targeted towards improving worker and equipment productivity, minimising energy use and benefiting human health and the environment.

By designing and manufacturing its own filter manufacturing machines, Camfil has full control over the process, ensuring air filter production meets the highest standards when it comes to energy efficiency.

Camfil’s range of products not only prioritise clean air but also reflects a commitment to the ever-evolving needs of customers, aligning with the principles of enhanced energy efficiency and improved life cycle costs. While traditional air filters typically feature a prefilter and a second filter to capture all particles, Camfil offers one filter with greater capacity and capability. This reduces the number of replacements, resulting in less wastage and supporting facilities to be more sustainable.

Camfil remains focused on continually improving the performance of its technology. In 2022, the company launched the latest upgrade to its Hi-Flo bag filters. Compared to the previous Hi-Flo series, the latest product has been designed to offer a 12% reduction in energy consumption and more than 30% better than the industry average.

Environmental Product Declarations have been developed for key products, including Hi-Flo, providing customers with detailed information on their environmental impact throughout the life cycle. By adopting solutions that offer transparency around carbon emissions and energy usage, businesses and consumers are better positioned to reduce their overall carbon footprint.

Since its inception, Camfil’s LCC software has helped thousands of healthcare facilities and other institutions around the world reduce both total energy expense and peak demand by objectively comparing filters from all manufacturers and identifying the most appropriate filter for each area.

Adopting energy-efficient, transparent air quality solutions can pave the way for industry-leading sustainability standards and initiatives such as the Green Building Council’s Green Star rating system or NABERS program. This showcases a businesses’ commitment to green practices and creating a more sustainable future for all.

PREV

NEXT

Comments

Advertisements

Recent news

- Additional keynote announced for HVAC26

- Dog days: how our best friends affect IAQ

- Cert II training and impact – have your say

Latest events

- Additional keynote announced for HVAC26

- PSO to host focus groups at AIRAH Hobart Industry Night

- Huge attendance for 2026 ASHRAE Winter Conference

Nick Johns-Wickberg

Nick Johns-Wickberg

Leave a Reply