The importance of vapour barriers in refrigeration

Bob Jackson, M.AIRAH, explains the importance of hermetically sealing the outer skin of cold rooms to create a vapour barrier.

You learn a lot working in your field. Many of those things only come with experience, not from a textbook.

Since 1964, the importance of vapour barriers in refrigeration has been drummed into me by various professionals, including my extremely knowledgeable mentor, Keith Greenhalgh. However, I believe many people working in our industry today haven’t had the training or experience to properly understand why vapour barriers are so important in cool rooms and freezer rooms.

I’ve written this article to share some of my experience on the issue.

Under (vapour) pressure

When we design a cold room, we always tell the builder to seal the outer skin, but we don’t tell them why it is so important. This article aims to do that, focusing on how vapour pressure can cause moisture ingress.

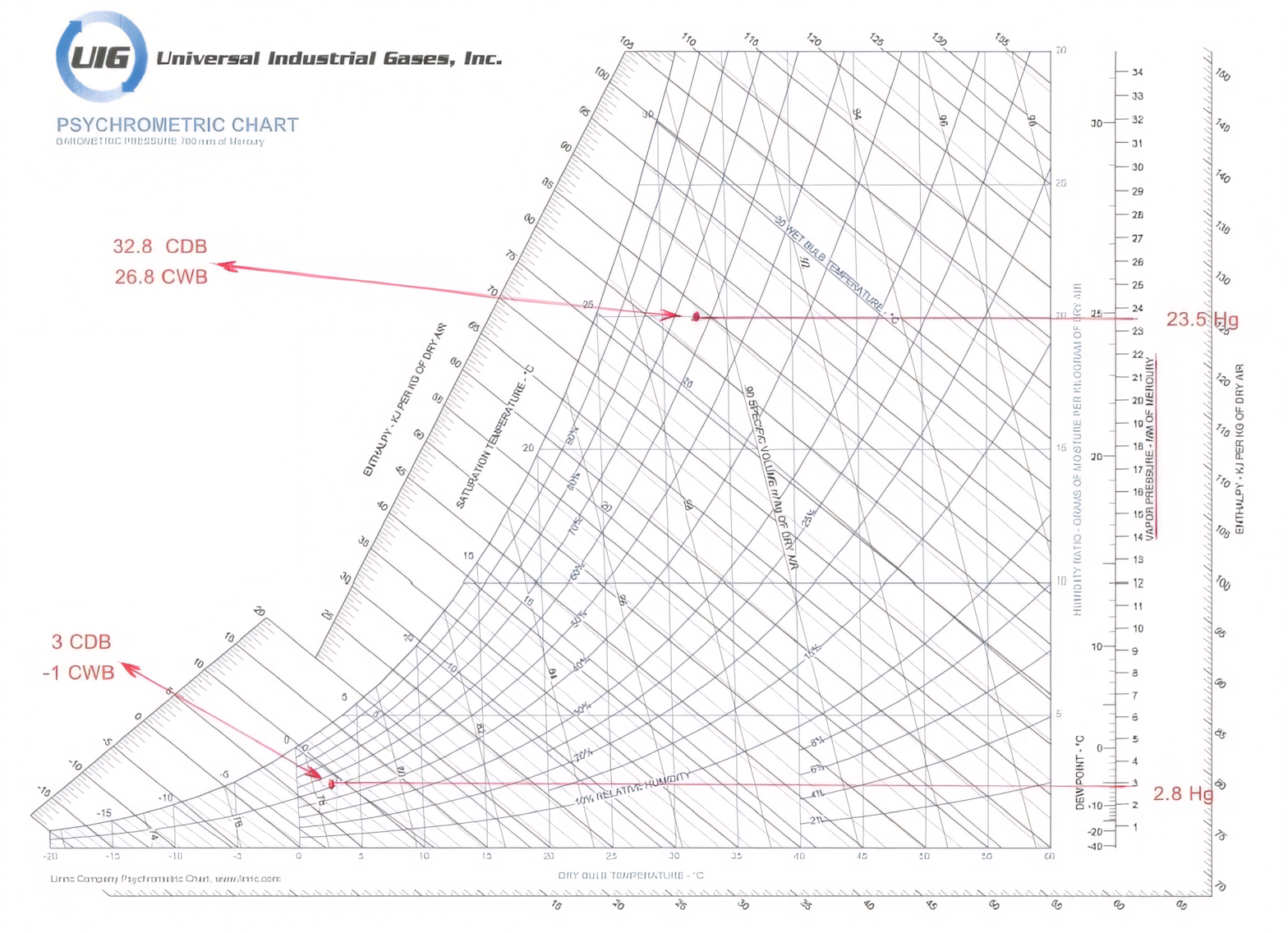

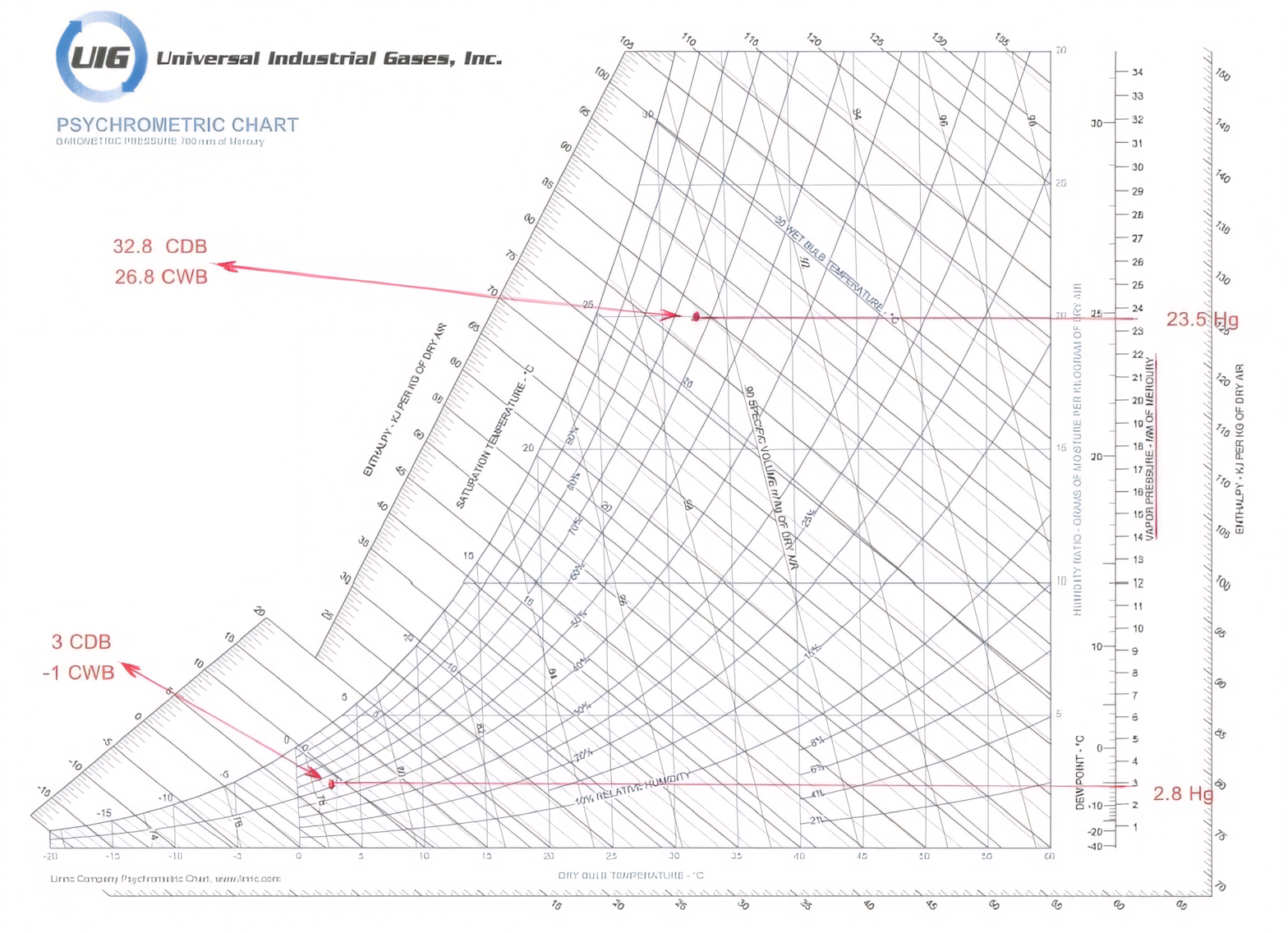

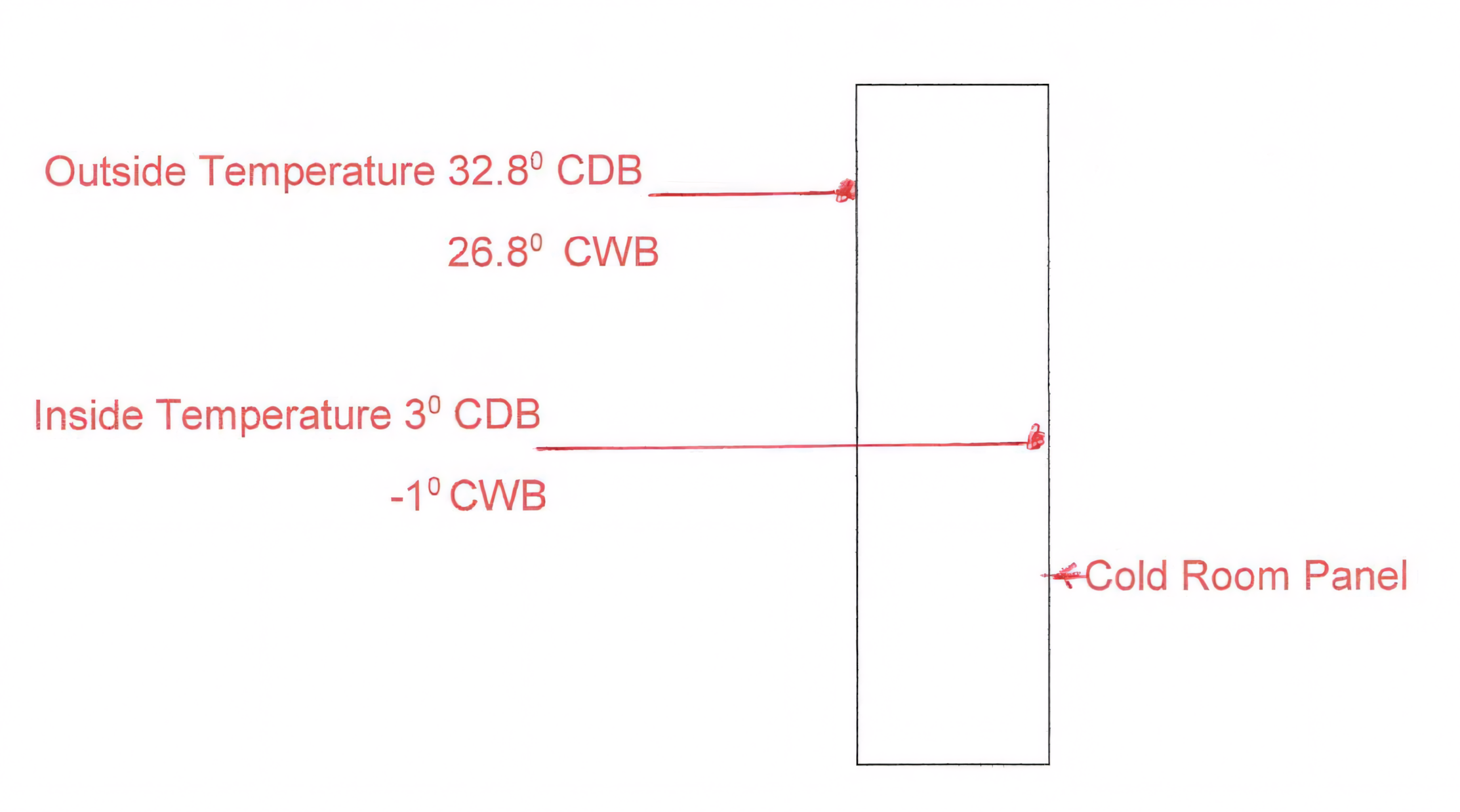

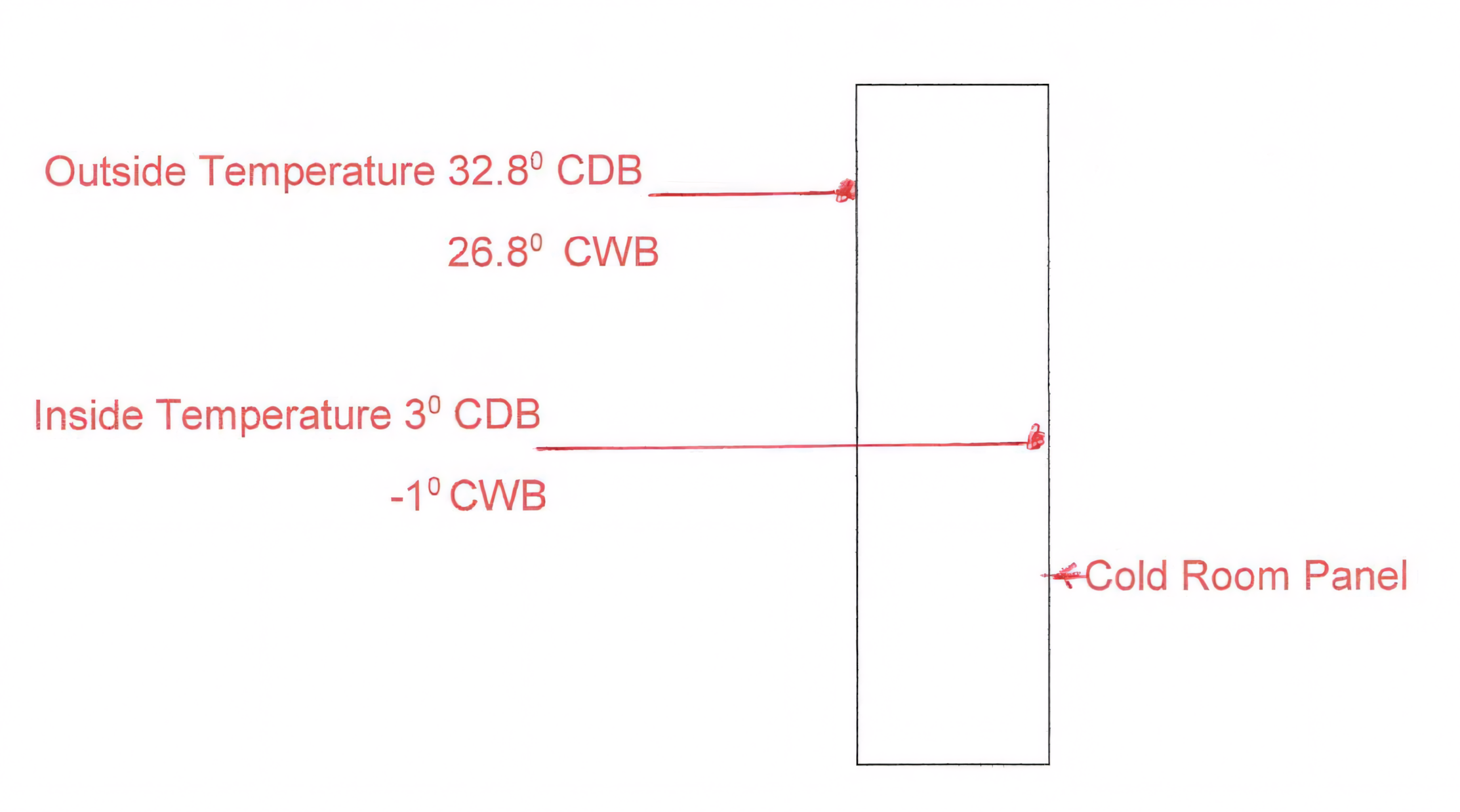

Let’s consider the conditions in my hometown, Cairns. The vapour pressure at design conditions for Cairns (32.8°C dry bulb and 26.8°C wet bulb) is 23.5mm of mercury (Hg). This can be seen in the psychrometric chart below.

The vapour pressure at the outside of the inner skin is 2.8mm of Hg. This means the vapour pressure difference between the two points is 20.7mm of Hg.

One mm of Hg equals 133.322 pascals (Pa), so the difference between the two points is 2,760Pa. If the outside skin is not hermetically sealed with a proper vapour barrier, the pressure difference between the two points will cause moist air to pass through the outer skin and into the insulation.

The above figures are for a medium temperature cold room. The vapour pressure difference is significantly larger for a freezer room.

How to create a vapour barrier

Hermetically sealing a cool room stops vapour ingress from degrading the insulation over time, as well as preventing moisture from collecting below the cool room itself.

So, how do we create this vapour barrier?

Our approach to hermetically sealing refrigerated spaces has evolved over the years. Until the late 1950s, cold rooms were built on site using cork insulation. The cork was coated with pitch to achieve a vapour barrier.

In the early 1960s, Australia became one of the first countries to use insulated sandwich panels, a development that revolutionised how we build cold rooms. The best way to hermetically seal a cold room or freezer room that uses sandwich panels is as follows.

Smaller cold rooms

In smaller cold rooms, the first step is to place a bead of butyl mastic along each internal surface of the external aluminium angles before they are riveted to all of the external corners. This includes all floor, ceiling and wall corners.

It’s also necessary to run a bead of mastic along one edge of the external slip joints on all floor, ceiling and wall panels before marrying them into one another. Panel manufacturers have provisions in the slip joint to accept this bead of mastic.

Once the cold room is constructed, door and service door inserts are installed. Take care to also seal around the outer edge of the door inserts.

Larger cold rooms

In larger rooms, the same process applies, but the vapour barrier under the floor is dealt with a little differently.

- First, fix the external aluminium floor angle to the structural concrete floor

- Run a generous bead of mastic along the horizontal face of the aluminium floor angle

- To create a vapour barrier, lay a strip of polyethylene film (such as Visqueen) approximately 300–400mm wide along the angle, pushing it into the bead of mastic. Laying the film under where the wall panels are being positioned allows work to be carried out without damaging the film that will eventually be installed in this area. It is imperative that the sealing integrity of the film is not compromised

- Lay a bead of mastic along the inside vertical face of the floor angle and assemble the room as previously described

- Once the room is fully constructed, lay out the film on the total internal floor area. Lay a generous bead of mastic along the previously installed film under the wall panels. If you need several strips of film for a large room, simply overlap the sheets at each joint and maintain the integrity of the vapour barrier by laying a generous bead of mastic between each overlapping sheet

- Place the floor insulation inside the room on top of the film.

Notes on rivets

There are rivets designed specifically for cold room construction. Unlike normal pop rivets, these are designed for the whole rivet to expand along their whole length, meaning they expand into the hole and create airtight conditions.

These are also known as “blind” rivets, meaning the expansion mandrel remains inside the rivet. These rivets also play an important role in maintaining the integrity of the vapour barrier. With standard rivets, there is no guarantee that the mandrel will remain in the rivet, so you could end up with an open hole through the centre of the rivet.

Don’t forget the slab

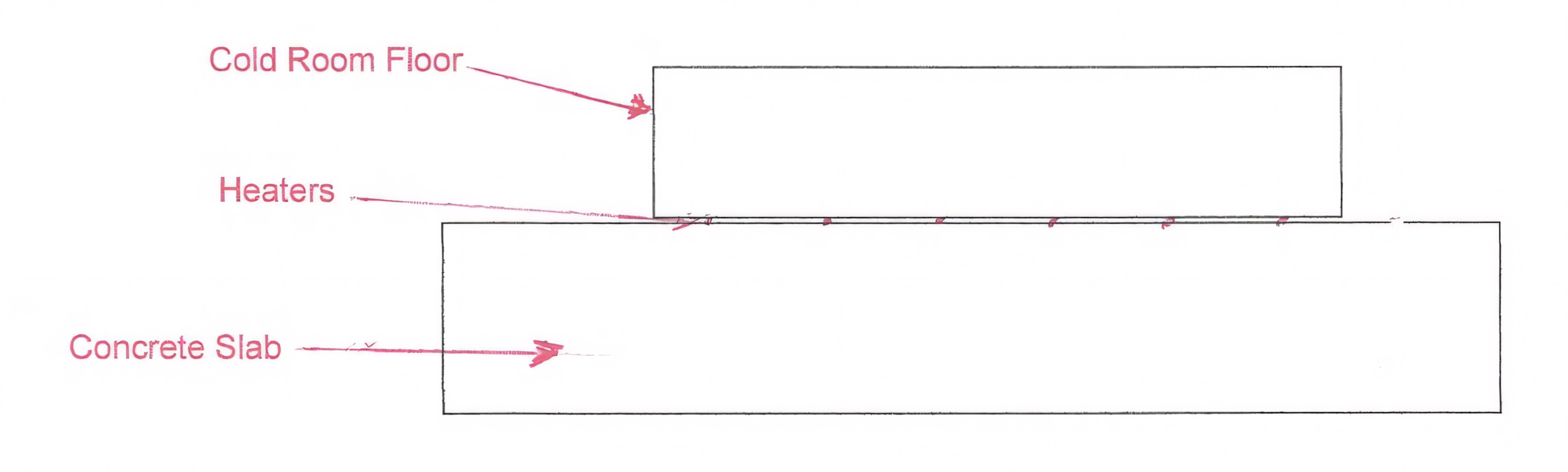

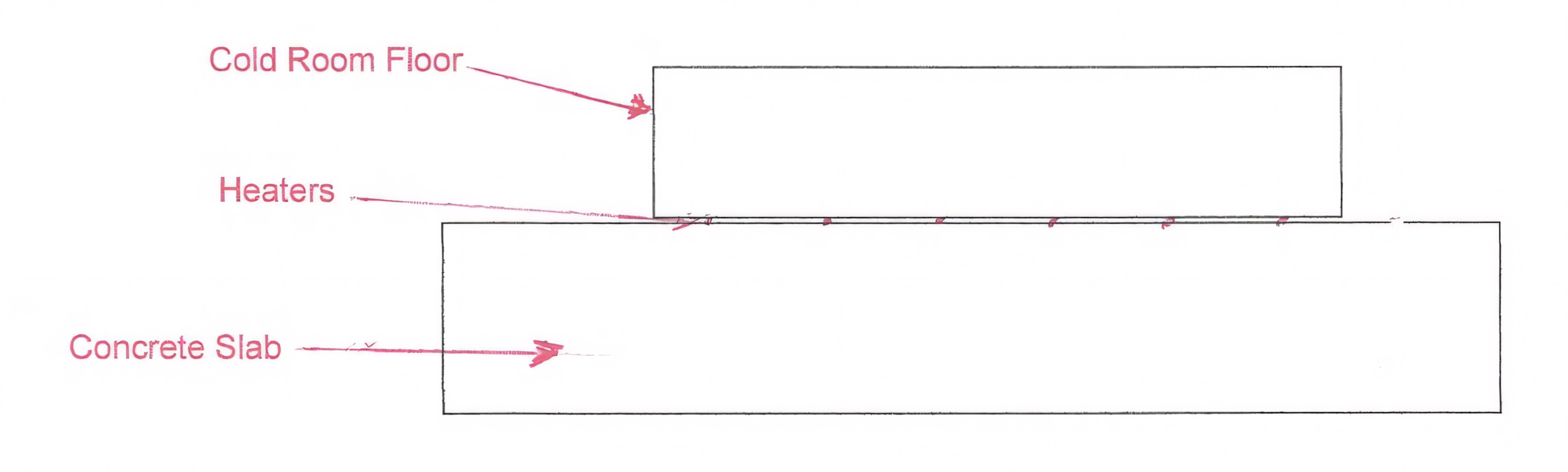

Sealing the sandwich panels isn’t the only step we need to take. A key but often overlooked aspect of sealing cold rooms is the concrete slab on which they’re built.

When a cold room is built on a suspended slab, sensible heat will flow from the slab over a period until it can reach a point where the temperature of the slab may fall below the dew point temperature of the air in the space below the concrete slab. Moisture forms on the underside of the slab, which can cause a real problem if there is tenancy below.

The solution is to install heating between the underside of the cold room and the top side of the concrete slab. This ensures that the temperature of the concrete slab remains above the dew point temperature of the space below.

There are multiple ways to heat the slab, with electric heaters being the most common. The wattage required differs between cold rooms and freezer rooms, and it’s best to install a spare heater as redundancy in case the original fails.

The downside of installing electric heating is the energy penalty, although this can be reduced by installing thicker insulation. It is advisable to install a pocket for a temperature sensor between the underside of the floor insulation and the top side of the structural slab so the heaters can be thermostatically controlled. The temperature of the slab here only needs to be above freezing (0°C).

To avoid the need for heating, some freezer complexes are built on a raised slab with an air gap between the underside of the concrete slab and the ground below. Another solution for freezers is to install slotted irrigation pipes at 900mm centres underneath the slab. The pipes need to be installed with a fall on them so that the ambient air will pass through them by natural convection. If natural convection doesn’t work, small fans can be installed to force air through the pipes. This method is called sub-floor ventilation.

Protecting against frost heave

For most cold rooms built on a concrete slab placed directly on the ground, sub-floor heating isn’t necessary. However, a freezer room bigger than approximately 6x6m built directly on the ground needs this sub-floor heating to prevent what is known as “frost heave”.

Frost heave occurs when the ground below the freezer falls below 0°C. The water in the ground turns to ice, expands, and “heaves” the building up with it. As you can imagine, frost heave can have disastrous structural consequences.

Real-world examples

Below are five real-world examples of how hermetically sealing cold rooms can be hugely beneficial down the track.

Standing the test of time

When my apprenticeship employer (K. M.Greenhalgh) started building cold rooms in 1964, the edges of every panel were hermetically sealed with marine varnish. This meant that if the vapour barrier of the room was compromised in any way, the panels did not become waterlogged, as they each had their own vapour barrier. We installed our first cold room at Silkwood Butchery in 1964 – it’s still in service more than 60 years later.

Lesson learnt

Many years ago, we installed a cold room in a temporary location until the customer’s new premises were ready for occupancy. We decided not to seal it with mastic, as it would have been very messy when we were dismantling and reinstalling the cold room in the new location. We thought that, but we were soon proven wrong! In just two months, the panels became quite waterlogged.

Cyclone-proof

After Cyclone Yasi, we got called to a job where an old Greenhalgh cold room had been smashed to pieces. That room had been in service for over 40 years. I retrieved a piece of the insulation and found it to be still in pristine condition, all thanks to a proper vapour barrier.

A great investment

In 2018, one of our customers purchased a hotel in Mareeba and called me to install a new main bar cold room. The original cold room was installed in 1970 by K. M. Greenhalgh, and the customer thought that after 48 years, the cold room would be completely waterlogged. We took samples of the cold room panels, and again they were in pristine condition; all the owner had to do was install modern glass door inserts and make some cosmetic adjustments, but not having to buy a new cold room saved him tens of thousands of dollars.

Added complications

In 2007, we built a new large freezer complex in Cairns. We hermetically sealed the exposed insulation on every edge of every panel, ensuring the insulation will be still dry decades down the track. Fortunately, we were dealing with a customer who could see the benefits of spending the extra money.

However, this project highlights a difficulty in maintaining the integrity of the vapour barrier on the outside skin of large complexes over many years. In a large freezer complex, the temperature could be -25°C on the inside skin of the panel and 35°C on the outside skin. The difference in temperature between the two skins causes the panels to move and damage the integrity of the vapour barrier, like you might see in a large bimetal strip. In large installations like this one, making “conduction cuts” in the panels can minimise this movement and extend the freezer room’s lifespan.

Conclusion

The above examples show why vapour barriers are so important. This principle doesn’t just apply to refrigerated cold rooms; vapour barriers are also important in applications such as air handling units, air conditioning ductwork and insulation on cold pipes.

We’ve all seen what goes wrong when vapour barriers aren’t installed properly. When they are, it makes a world of different to both HVAC&R technicians and their clients.

Acknowledgements

The author thanks to the following people for reviewing this article:

- Sonia Holzheimer, M.AIRAH, Principal Mechanical Engineer at Sequal Consulting Group

- The late Graeme Standfield, F.AIRAH – an extremely competent mechanical engineer whom I knew for many years

- Glenn Davies, Manager at Actrol.

For more information about cold rooms and how to improve energy efficiency, refer to AIRAH’s DA12: Energy Efficiency in Cold Rooms manual.

About the author

Bob Jackson, M.AIRAH, began his HVAC&R career as an apprentice at K. M. Greenhalgh in November 1962. Over his decades working in the trade in Cairns, he and his son have trained more than 100 apprentices with a focus on innovation and cutting-edge practices.

PREV

NEXT

Comments

-

An excellent article highlighting how essential vapour barriers are in coldroom design and construction. I learned these lessons in 1970 when I designed my first coolroom and applied the principles to every one of the hundreds of coldroom I designed throughout my career. None of the rooms I designed ever had a problem but I have seen plenty of others that have.

The vapour sealing requirements also apply to air conditioned buildings in humid climate zones 1 & 2, which is poorly understood and not adequately dealt with in the NCC. -

Very useful article. We have just designed a new mortuary in Darwin and this will come in handy.

Advertisements

Recent news

- Cert II training and impact – have your say

- New studies explore causes and consequences of TFA accumulation

- QUT researchers use AI to optimise urban greening

Latest events

- PSO to host focus groups at AIRAH Hobart Industry Night

- Huge attendance for 2026 ASHRAE Winter Conference

- Final call for 2026 ARBS Awards nominations

Bob Jackson, M.AIRAH

Bob Jackson, M.AIRAH

Leave a Reply