Researchers develop cardboard-based rammed earth

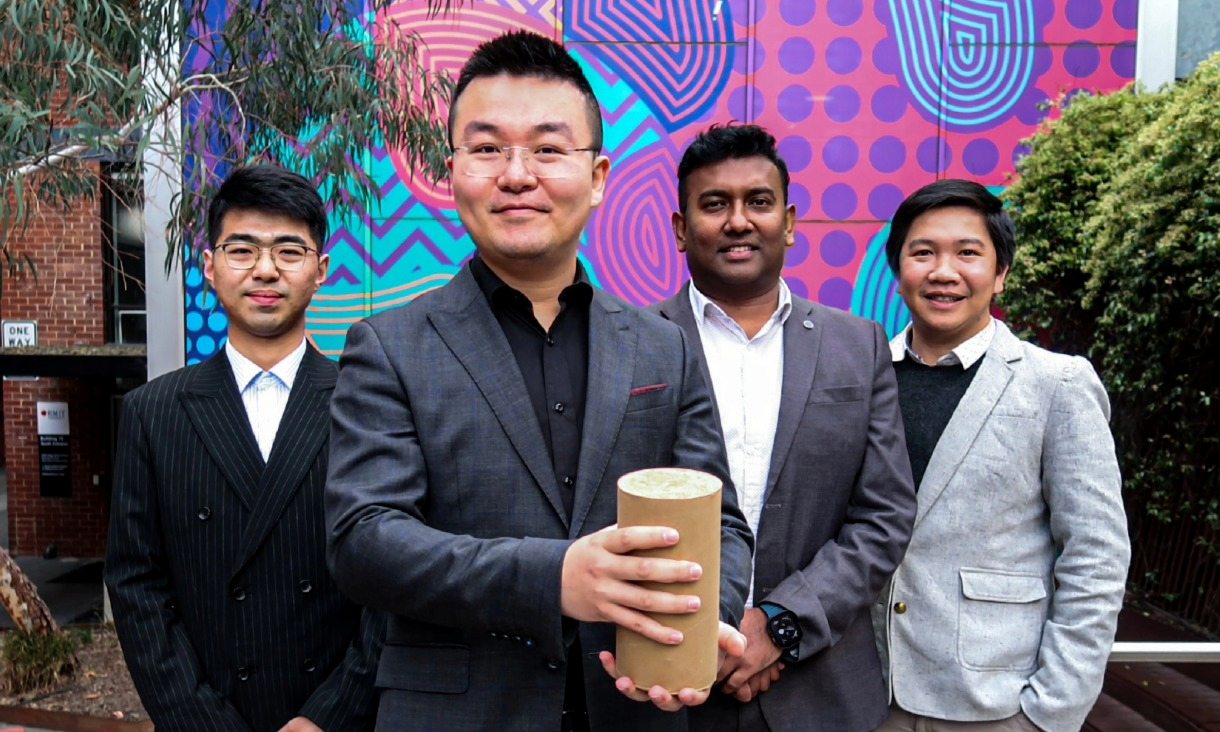

Engineers at RMIT have created “cardboard-confined rammed earth”, a construction material composed entirely of cardboard, water and soil.

Traditional rammed earth techniques are carbon-intensive, primarily because of their use of cement. Cardboard-confined rammed earth eliminates the need for cement, meaning it has roughly a quarter of the carbon footprint of concrete at under a third of the cost. Cement and concrete production account for about 8% of annual global greenhouse gas emissions.

RMIT says the reusable and recyclable material could make use of around 2.2 million tons of cardboard and paper that end up in Australian landfill every year.

Multiple benefits

Lead author Dr Jiaming Ma from RMIT says the material makes sense for both practical and environmental reasons.

“Modern rammed earth construction compacts soil with added cement for strength,” Ma says. “Cement use is excessive given the natural thickness of rammed earth walls.

“By simply using cardboard, soil and water, we can make walls robust enough to support low-rise buildings.”

Dr Jiaming Ma

“This innovation could revolutionise building design and construction, using locally sourced materials that are easier to recycle. It also reflects the global revival of earth-based construction fuelled by net zero goals and interest in local sustainable materials.”

Onsite fabrication

RMIT says the cardboard-confined rammed earth can be made on the construction site by compacting the soil and water mixture inside the cardboard formwork, either manually or with machines.

Study corresponding author Emeritus Professor Yi Min “Mike” Xie says this advancement can spearhead a leaner, greener approach to construction.

“Instead of hauling in tonnes of bricks, steel and concrete, builders would only need to bring lightweight cardboard, as nearly all material can be obtained on site,” Xie says.

“This would significantly cut transport costs, simplify logistics and reduce upfront material demands.”

Ma says cardboard-confined rammed earth could be an effective solution for construction in remote areas, such as regional Australia, where red soils – ideal for rammed earth construction – are plentiful.

“Rammed earth buildings are ideal in hot climates because their high thermal mass naturally regulates indoor temperatures and humidity, reducing the need for mechanical cooling and cutting carbon emissions,” he says.

Calculating mechanical strength

The mechanical strength of the novel material varies based on the thickness of the cardboard tubes.

Ma says the team has developed the formula for this strength design.

“We’ve created a way to figure out how the thickness of the cardboard affects the strength of the rammed earth, allowing us to measure strength based on cardboard thickness,” Ma says.

In a separate study lead by Ma, carbon fibre was combined with rammed earth, proving it had comparable strength to high-performance concrete.

Read the full study

You can access the full study via Science Direct.

Images courtesy of RMIT

PREV

NEXT

Comments

Advertisements

Recent news

- Updates to NABERS embodied carbon

- Like shelling pea(nut)s: UNSW researchers make graphene breakthrough

- The path ahead for the VEU – industry webinars

Latest events

- The path ahead for the VEU – industry webinars

- Additional keynote announced for HVAC26

- PSO to host focus groups at AIRAH Hobart Industry Night

Nick Johns-Wickberg

Nick Johns-Wickberg

Leave a Reply