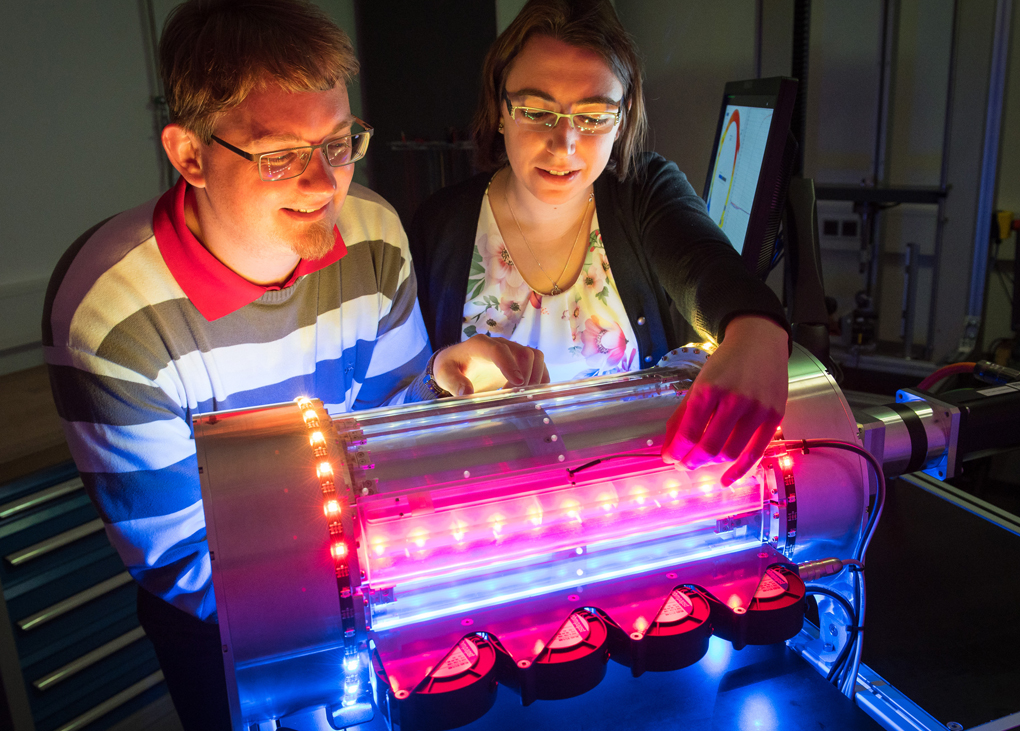

A research team at Germany’s Saarland University has developed a prototype device that can transfer heat using “muscles” made from nickel-titanium.

Nickel-titanium is a shape-memory material that releases heat to its surroundings when it is mechanically loaded in its superelastic state. It absorbs heat from its surroundings when it is unloaded.

The team, led by Professors Stefan Seelecke and Andreas Schütze, believe the prototype system is up to three times more efficient than conventional heating and cooling devices.

“Our system does without the conventional refrigerants that are so damaging to the environment,” explains Schütze.

The underlying principle involves subjecting a particular shape-memory alloy to controlled loading/unloading cycles.

Seelecke says the resulting phase transitions that occur in the alloy’s crystal lattice either release or absorb latent heat, depending on which part of the cycle the material is in.

The team has designed and developed a patent-pending cam drive, whose rotation ensures that bundles of 200 micron-thick nitinol wires are alternately loaded and unloaded so that heat is transferred as efficiently as possible. Air is blown through the fibre bundles in two separate chambers: in one chamber the air is heated, in the other it is cooled. The device can therefore be operated either as a heat pump or as a refrigerator.

The engineers at Saarland University and at Zema (Center for Mechatronics and Automation Technology) in Saarbrücken have spent a number of years working on the problem in different projects, including the DFG-funded priority programme “Ferroic Cooling“.

Using a combination of experimental investigations and numerical modelling, they were able to identify how to maximise the efficiency of the underlying mechanism, the wire loading level needed to achieve a specific degree of cooling, the ideal rotational speed and how many nitinol wires need to be included in a bundle.

The team is currently working on further optimising heat transfer within the system in order to boost the efficiency of the new technology even more.

The objective is to get to a stage where almost all of the energy from the phase transition is being used for heating or cooling.

Photo: Oliver Dietze

Leave a Reply