The ionair Air Quality System (AQS) is designed to be incorporated in the supply air of an HVAC system to improve the air quality and hygiene in the ventilated room. This includes identifying and reducing odours both from inside and outside the room.

The system can either be incorporated during the planning phase for a new construction by the HVAC designer or retrofitted in existing buildings.

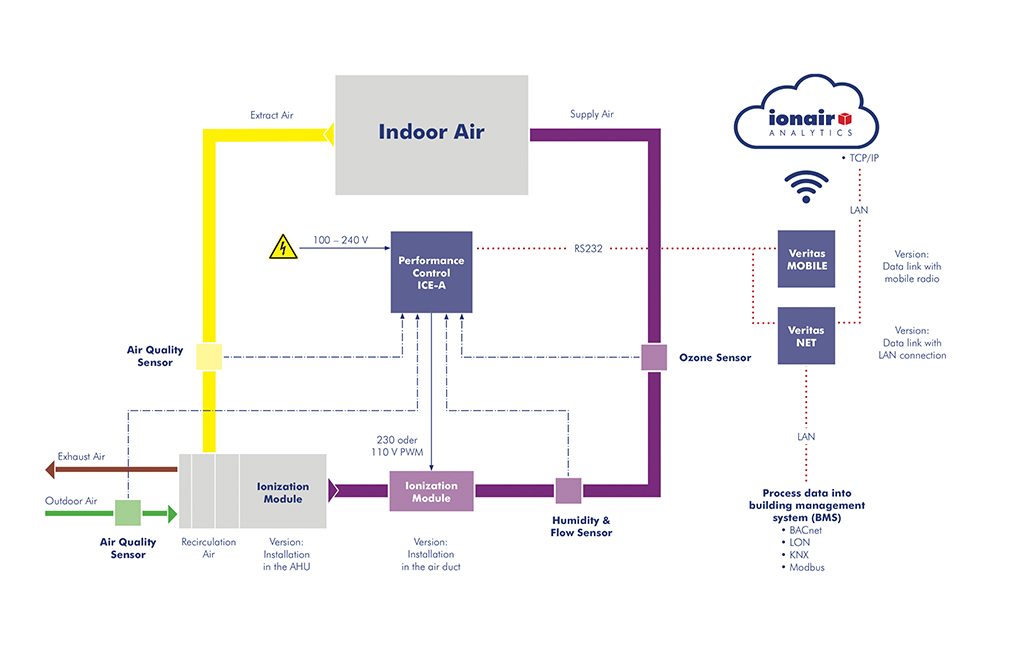

Based on sensor signals, the Ionair power controller can determine the ionisation intensity as required on the basis of the outdoor air quality, the indoor air quality, the air volume and the humidity. If the permissible ozone level is exceeded, the ozone sensor makes a note of this and the controller reduces the ionisation intensity accordingly.

“Our leading Air Quality System with its five air quality sensors, sets us apart from our competitors and we have found over the past year during this unprecedented COVID time it is extremely important to control the overall quality and hygiene levels of the air we breathe in any building,” says the company.

“Our ionair system treats the air in the space – it is not limited to local effects. The Air Quality System (AQS) of ionair means targeted improvement in all aspects of the air we breathe. Germs, bacteria and mould spores are minimised up to 95 per cent effectively with our system. Air bi-polar ionisation produces an odourless, hygienic and a safe indoor climate for all.”

According to the company, the ionair AQS has received more than favourable Fraunhofer IBP test results on the reduction of the viruses in indoor air.

The Fraunhofer Institute for Building Physics (IBP) was appointed to test the reduction and inactivation of airborne surrogate viruses – non-pathogenic covered Phi6 bacteriophages with structure, particle size and environmental stability equivalent to that of SARS-CoV-2 – by the AQS.

The analyses were reportedly conducted under as real conditions as possible in a 175m³ large, stainless steel room. The surrogate viruses were dosed continuously, and the viruses were collected from the indoor air and processed in the laboratory, and the number of viruses was determined with the help of the plaque assay method.

“The ionair AQS reduces the concentration of viruses in the range of 99.49 per cent to 99.59 per cent, while complying with all statutory and health-related limit values for indoor air, including ozone and formaldehyde, even with a continuous virus load,” says Ionair.

“Thanks to the more than favourable Fraunhofer IBP test results on the reduction of the viruses in indoor air with the ionair AQS, we now have another technical measure available that permits us to find our way back faster and far more safely to a normal economic and social life.”

Ionair is a global organisation based in Lucerne, Switzerland with offices in Europe, Asia, America and Australia.

Leave a Reply